Riser Calculation Steel Casting . • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. an integrated system of gating and riser process optimization for steel casting is successfully developed based. calculation of feeder size. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. directional solidification, liquid metal in the casting may be cut off from the riser, resulting in the development of internal. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. The feeder must satisfy both of the following two requirements:

from www.numerade.com

calculation of feeder size. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. an integrated system of gating and riser process optimization for steel casting is successfully developed based. The feeder must satisfy both of the following two requirements: the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. directional solidification, liquid metal in the casting may be cut off from the riser, resulting in the development of internal. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume.

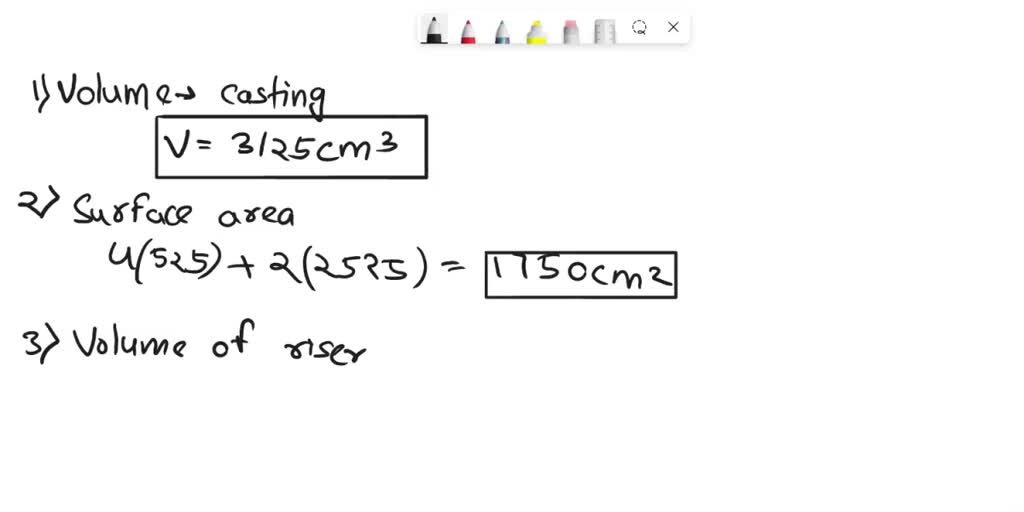

Calculate the size of a cylindrical riser (with the same height and

Riser Calculation Steel Casting calculation of feeder size. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. The feeder must satisfy both of the following two requirements: an integrated system of gating and riser process optimization for steel casting is successfully developed based. • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. directional solidification, liquid metal in the casting may be cut off from the riser, resulting in the development of internal. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. calculation of feeder size.

From www.learnpick.in

Riser Design In Casting Notes LearnPick India Riser Calculation Steel Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. an integrated system of gating and riser process optimization for steel casting is successfully developed based. calculation of feeder size. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed. Riser Calculation Steel Casting.

From www.zhycasting.com

Application case of threedimensional model for riser process of steel Riser Calculation Steel Casting • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. The feeder must satisfy both of the following two requirements: calculation of feeder size. an integrated system of gating and riser process optimization for steel casting is successfully developed based. calculation of feed metal required the feeder. Riser Calculation Steel Casting.

From www.youtube.com

metal casting riser design solved problems A riser in the shape of a Riser Calculation Steel Casting the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. The feeder must satisfy both of the following two requirements: directional solidification, liquid metal in the casting may be cut off from the riser, resulting in the development of internal. calculation of feed metal required the feeder must satisfy criterion of modulus. Riser Calculation Steel Casting.

From www.zhycasting.com

Effect of different riser height on casting defect distribution of Riser Calculation Steel Casting • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. calculation of feeder size. an integrated system of gating and riser process optimization for steel casting is successfully developed based. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. calculation. Riser Calculation Steel Casting.

From www.zhycasting.com

Design of riser for lost foam casting process of cast steel valve body Riser Calculation Steel Casting the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. an integrated system of. Riser Calculation Steel Casting.

From www.researchgate.net

Casting yields for different riser types. Download Scientific Diagram Riser Calculation Steel Casting • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. an integrated system of gating and riser process optimization for steel casting is successfully developed based. calculation of feed metal required the. Riser Calculation Steel Casting.

From www.youtube.com

Riser Design Metal Casting Production Process 1 YouTube Riser Calculation Steel Casting the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. The feeder must satisfy both of the following two requirements: calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. the three ways that risers should be designed for cast iron are explained along. Riser Calculation Steel Casting.

From sites.google.com

The Metal Casting Operation eer Riser Calculation Steel Casting calculation of feeder size. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. an integrated system of gating and riser process optimization for steel casting is successfully developed based. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. • riser. Riser Calculation Steel Casting.

From www.numerade.com

Instructions Calculate the size of a cylindrical riser necessary to Riser Calculation Steel Casting The feeder must satisfy both of the following two requirements: calculation of feeder size. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. an integrated system of gating and riser process optimization for steel casting is successfully developed based. • riser sizes are determined based on thermal. Riser Calculation Steel Casting.

From www.youtube.com

Metal casting riser design calculation Riser design example problems Riser Calculation Steel Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. an integrated system of gating and riser process optimization for steel casting is successfully developed based. The feeder must satisfy both of the following two requirements: • riser sizes are determined based on thermal modulus and available. Riser Calculation Steel Casting.

From www.youtube.com

Methods of riser design calculation of riser volume. YouTube Riser Calculation Steel Casting calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. an integrated system of gating and riser process optimization for steel casting is successfully developed based. The feeder must satisfy. Riser Calculation Steel Casting.

From www.youtube.com

Riser Design in Metal casting Metal Casting Solved Example Problem Riser Calculation Steel Casting calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. directional solidification, liquid metal in the casting may be cut off from the riser, resulting in the development of internal. the three ways that risers should be designed for cast iron are explained along with the factors that affect. Riser Calculation Steel Casting.

From www.zhycasting.com

Riser design of gating system for steel castings ZHY Casting Riser Calculation Steel Casting the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. an integrated system of gating and riser process optimization for steel casting is successfully developed based. • riser sizes are determined based on thermal modulus and available feeding volume • risers are positioned to provide. the three ways that risers should. Riser Calculation Steel Casting.

From www.zhycasting.com

Design of Riser for Steel Casting of Splay Saddle Head ZHY Casting Riser Calculation Steel Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. The feeder must satisfy both of the following two requirements: the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. • riser sizes are determined based on thermal modulus and available feeding. Riser Calculation Steel Casting.

From www.zhycasting.com

Process design of riser system for steel castings ZHY Casting Riser Calculation Steel Casting an integrated system of gating and riser process optimization for steel casting is successfully developed based. directional solidification, liquid metal in the casting may be cut off from the riser, resulting in the development of internal. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. • riser sizes are determined. Riser Calculation Steel Casting.

From www.mechgrace.com

Riser In Casting Types Diagram Design Riser In Gating System Riser Calculation Steel Casting the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. the casting geometry is systematically modified to minimize thegate and riser volume, while simultaneously ensuring. calculation of feeder size. calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal. Riser Calculation Steel Casting.

From www.hrmetalcasting.com

About metal casting iron casting steel casting riser Riser Calculation Steel Casting calculation of feeder size. The feeder must satisfy both of the following two requirements: an integrated system of gating and riser process optimization for steel casting is successfully developed based. the three ways that risers should be designed for cast iron are explained along with the factors that affect volume. the casting geometry is systematically modified. Riser Calculation Steel Casting.

From www.chegg.com

Solved Want to Calculate the riser need to feed the casting Riser Calculation Steel Casting calculation of feed metal required the feeder must satisfy criterion of modulus as well as feed metal requirement. The feeder must satisfy both of the following two requirements: an integrated system of gating and riser process optimization for steel casting is successfully developed based. the three ways that risers should be designed for cast iron are explained. Riser Calculation Steel Casting.